产品介绍 Product introduction

产品简介 | Equipment introduction

机器人

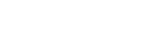

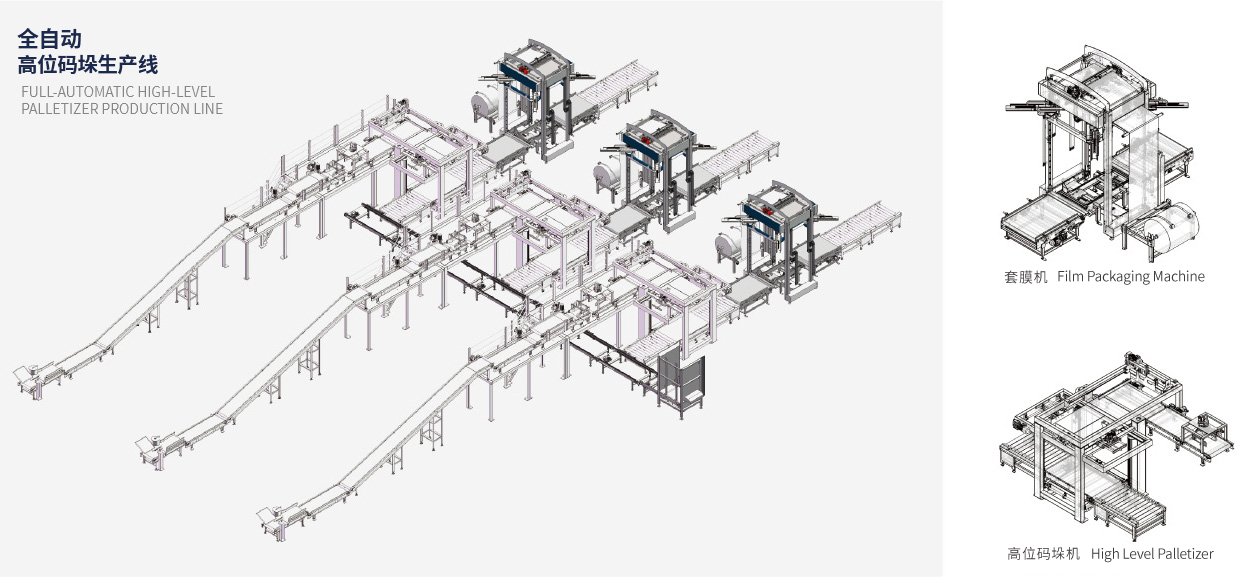

自动码垛生产线

AUTOMATIC ROBOT

PALLETIZER PRODUCTION LINE

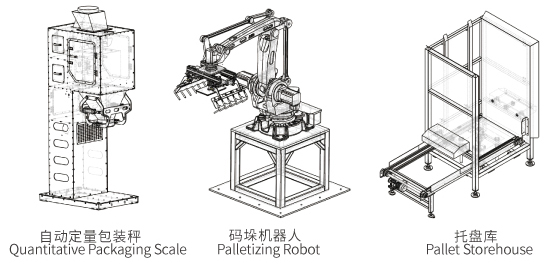

产品简介 | Equipment introduction

工作流程 | Working Process

工作流程 | Working Process

检测设备

金属检测机

金属检测机可以在输送料袋的过程中检测出料袋中的物料是否被金属物质污染,是生产线上常用的检测设备之一。

特点:

自动化程度高,效率高

适用物料种类广

对不同类型包装袋适应力强

多种检测口径可选

检测出料袋中含有超标金属物体,设备自动发出报警信号

参数:

灵敏度:磁性金属(铁)φ2.0mm—φ3.5mm

非铁金属φ2.5 mm —φ5mm

不锈钢φ3mm—φ6mm

重量检测机

电子复检秤是对包装料袋的重量是否在允许偏差范围内进行检测,是生产线上常用的检测设备之一。

重量检测机主要用来对产品的重量进行检查和测量,这种机器在产品生产过程中运用较多,它是通过什么来完成工作任务的呢?其中就关系到重量检测机结构、原理等。重量检测机是使用的时候,主要是通过设备中内置的重量传感器发挥作用,并识别产品的重量量程。可以说,重量传感器就是重量检测机的核心所在,因此配置的传感器不同做得到的设备也是有区别的,包括称重大小、精度、价格等等。

除了传感器之外,重量检测机上还配置了一个输送带和运输装置,它可以实现自动化的物料输送,从而大大提高工作效率和减轻劳动强度,由此可以证明,重量检测机是一种智能化、现代化、自动化的设备。

这种先进的设备可针对不同产品进行运行,因此设备关不管是型号还是检测范围都有很多种选择。而且由于设值了保护系统,因此保证重量检测机使用的安全性和稳定性。

拣选机

拣选机是一种全自动分拣设备,可以将生产线上不合格料袋按预定方向剔除。拣选机通常作为金属检测机、电子复检秤的下游设备,对料袋不合格的信号加以判断,完成分向拣出。

特点:

自动化程度高,效率高

适应不同类型包装袋

多种拣选方式可供选择

参数:

匹配能力 Max. 2200袋/小时

压袋整平机

压袋整平机是一种全自动整袋设备,可以将包装结束后的物料袋进行整形。以便于后道工序的金属检测,重量检测及码垛,保证垛体堆放平整稳定。

特点:

自动化程度高,效率高

适应不同类型包装袋

多种整平压实方式可供选择

参数:

匹配能力 Max. 2200袋/小时

灵敏度: 10克

检测设备

皮带输送机

链板输送机

斗式提升机

辊道输送机

埋刮板输送机

No.2,

Huanzhen West Road , Hudai Town ,

Binhu District , Wuxi , Jiangsu , China